WATERJET CUTTING

NEED ACCURATE CUTS ON THICK OR THERMALLY SENSITIVE MATERIAL?

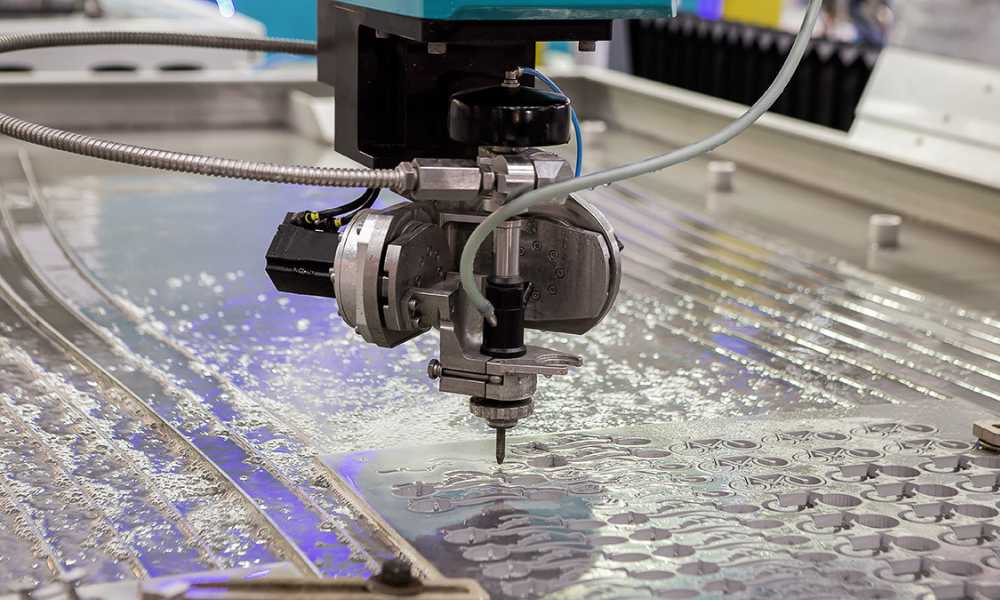

Waterjet cutting is a versatile cutting method that uses a high-pressure stream of water (usually mixed with an abrasive media) to cut a wide range of materials into shapes and designs. Compared to other cutting processes, such as plasma or laser cutting, it offers several advantages, including better accuracy, the accommodation of more complex part designs, and the ability to cut thicker or thermally sensitive materials.

Water is first pressurized to around 50,000 psi to 60,000 psi. After that is done, the water is passed to a ruby or diamond nozzle through a high-pressure tube. It is the nozzle that ejects water from the waterjet cutter.

The nozzle used here has to have a small diameter, usually between 0.1 and 0.4mm. Because of the small bore, the cutter concentrates the pressure and ejects a narrow beam of water.

As the water leaves the nozzle, the pressure converts into extremely high velocity, between Mach 2 and Mach 3. This narrow ultra-pressurized beam is what we call the waterjet. The force of the waterjet is intense and is responsible for precise and clean cutting.

WORK WITH US ON YOUR NEXT PROJECT

YEARS OF INDUSTRY EXPERIENCE

Completed Projects

ITAR Registered

ITAR compliance requires a significant commitment from management and substantial investment in systems. Excel Manufacturing Inc. far exceeds ITAR requirements.

Traceable Calibration

Excel Manufacturing Inc. prides itself on providing our customers with the highest quality products. Our calibration equipment has an unbroken chain of measurement leading back to NIST-maintained standards.

State-Of-The-Art Machining Services

Excel is continuously investing in its capabilities in order to provide the best possible services and products to its customers.

THE BENEFITS OF WATERJET CUTTING

A waterjet cutter has a wide range of applications and can cut irregular shapes from almost any material with exceptional precision and edge quality. Curves, straight cuts, internal holes, and lettering once cut by hand can now be cut in a fraction of the time by waterjet.

SUPERIOR EDGE QUALITY

Edge quality is one of the most important significant reasons why designers specify waterjet. Waterjet produces a smooth uniform burr-free edge.

The edge quality produced by waterjet is a function of speed, pressure, nozzle size, and abrasive flow rate. In many cases waterjet eliminates the need for secondary finishing, thus creating significant time savings and improving efficiency.

PRECISE INTERNAL CUTOUTS

With cutting accuracy of ±0.038 to ±0.2mm (accuracy varies between machines), waterjet is an extremely versatile cutting tool which is why it is used in many industries for intricate designs and jobs which require high tolerances.

NO HEAT AFFECTED ZONES

Waterjet is a cold cutting process that eliminates problems caused by heat distortion and hardened edges. This is particularly advantageous for intricate metal fabrication and products which require additional machining after cutting.

Any cutting process which generates heat has the secondary effect of changing the molecular structure of the steel in the affected zone. This can be particularly detrimental to the performance of steels used in specialized applications.

INCREASED CUTTING FLEXIBILITY

The flexibility to be able to efficiently cut almost any job is one of the key reasons waterjet is such an attractive option.

We are proud to manufacture our products 100% in the USA.

Client Testimonials

"Excel Manufacturing Inc. dropped what they were doing to help me out. Greatly appreciate their service"

"Excel Manufacturing Inc. squeezed in a part last minute to make the following possible. The part came as requested without defects or retouches necessary."

"These people give wonderful customer service. They got my jobs done in a timely manner and with high quality!"